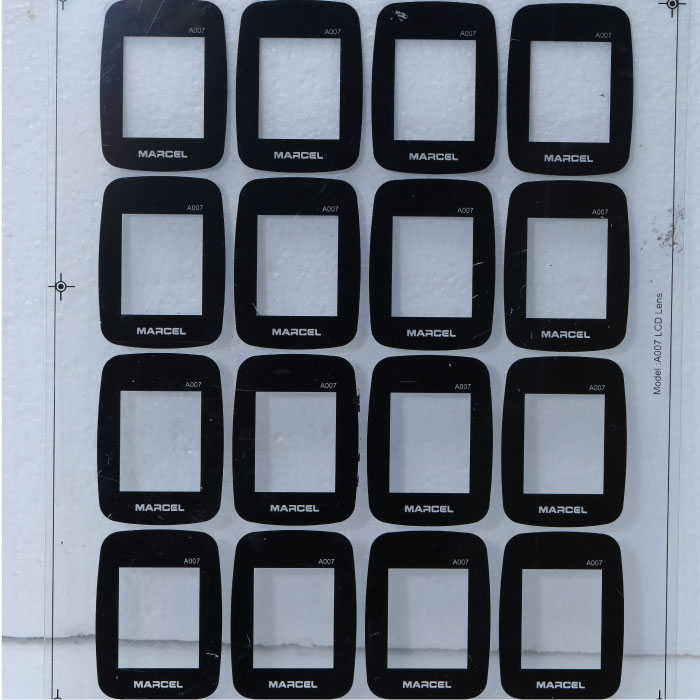

Description

Raw Materials: Poly Carbonate (PC) sheet, Black & Silver ink, Hardner, Reducer, Poly paper.

Machine Used: CNC Cutting Machine, Thermal Chamber, Poly Rapping Machine, Lamp Testing Machine.

Manufacturing Process:

Waltons’ featurephone lens production process involves a combination of advanced machines to ensure precision and quality.Initially a Block printing machine is used, where the black border design of the model using composite of black ink, hardner and reducer as well as silver ink for the ingraving of the model numbers are done. Once it is applied, the lens moves Thermal chamber for the ink to engrave on the PC sheet. After this, the lens goes through Lamp testing machine for QC check the border quality to ensure proper quality. Then the QC pass blocks moves to the Poly Rapping machine for better protection from any kind of scratch before going to cutting and drilling machine. At the heart of the operation is a CNC machine, utilizing computer-controlled technology to automate the accuracy and efficiency of the production process with precise cutting and drilling.These cutting-edge machines work in harmony, ensuring the creation of high-quality lenses that meet the demanding standards of the optical industry. At the final stage, the lens pass through cleaning machine then goes to rapping machine for delivering to the customer.