Description

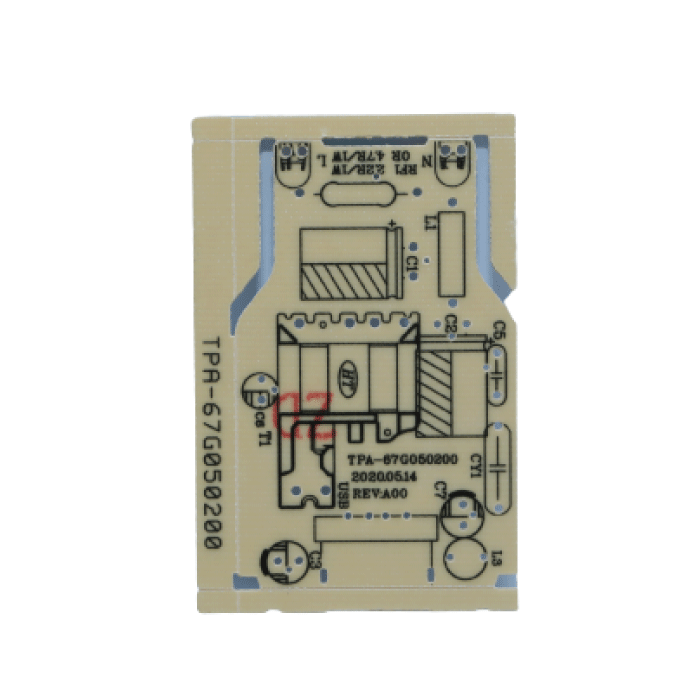

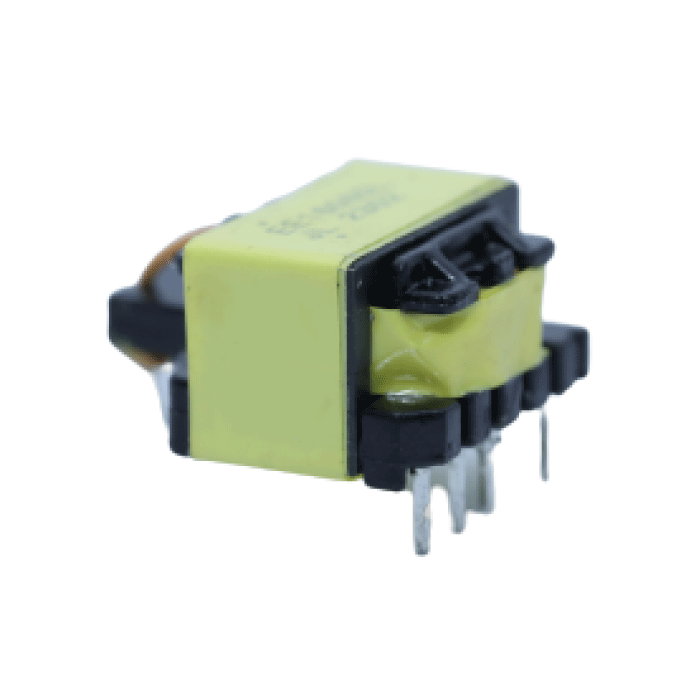

Raw materials: PCB, SMD components, inductors, capacitors, transformers, electrolytic capacitors, Y capacitors, USB pin and metal pins

Machines used: Air web soldering machine, manual soldering machine, ATA machine, Ultrasound welding machine, Ageing machine.

Manufacturing process: Firstly inductors, capacitors, transformers, electrolytic capacitors, Y capacitors, USB pin and metal pins are placed by applying proper technique to ensure reliable connections. A flux machine is involved to ensure flux before web soldering. Air web soldering machine is used to solder the components. These machines contribute to the mass production of chargers in WALTON with high precision and consistent quality, meeting the demands of the chargers in mobile industry. If there is any soldering issue, it will be solved manually. After checking all soldering components visually, all the PCBA’s in batch are checked via ATA machine. All the functional parameters are preset in ATA machine. Passed PCBA’s have been separated from batch and assembled with housing. After assembly each and every charger is re-checked with ATA machine. Ultrasound welding machine is used for joining upper housing of chargers. Chargers often have plastic enclosures that house various components. Ultrasonic welding is effective in joining plastic parts together, providing a strong and durable bond. It is commonly used to assemble charger casings, ensuring proper alignment and structural integrity. To check charger reliability, aging test is conducted by charger ageing machine.