Description

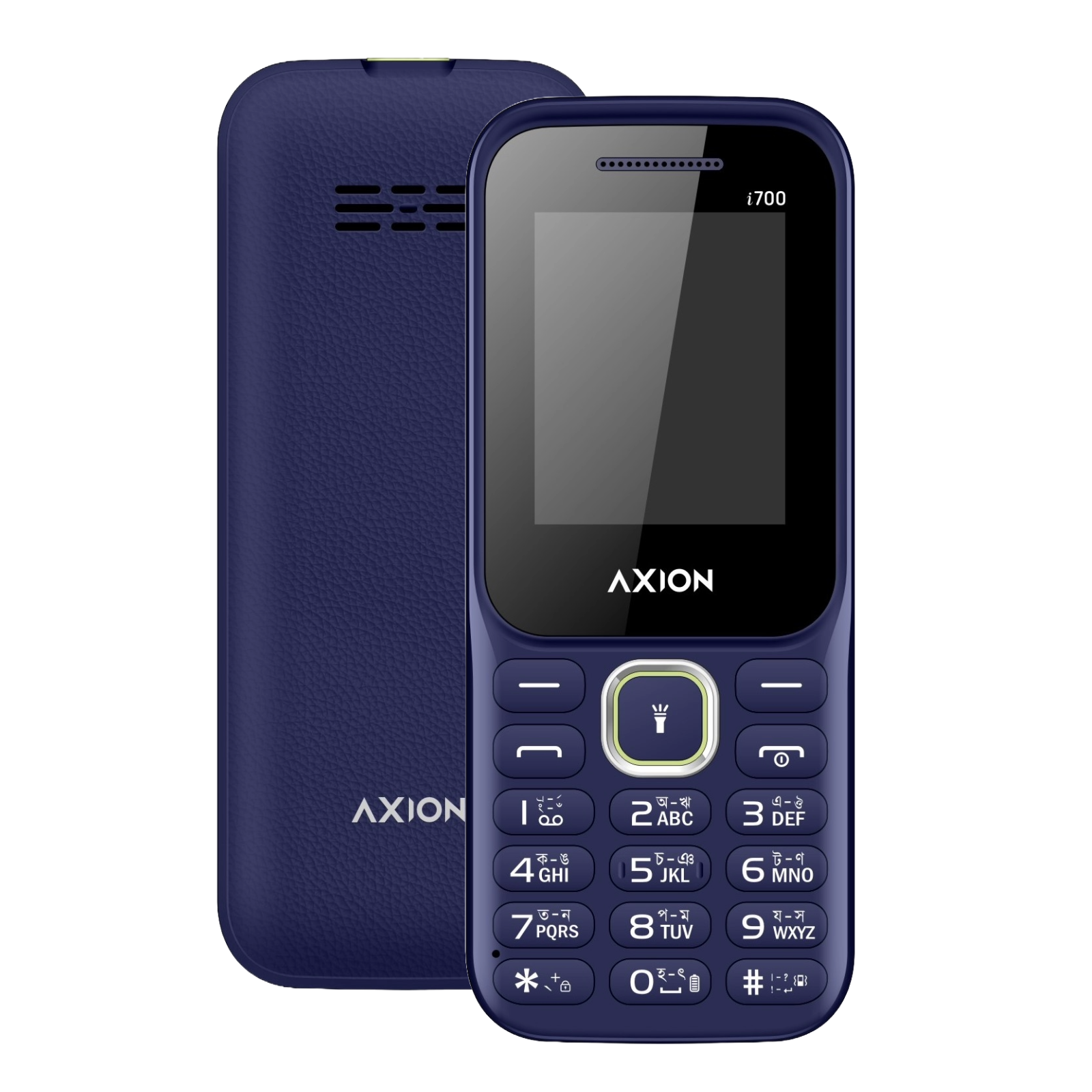

Raw materials: PCBA, LCD, battery, LCD lens, camera lens, torch, keypad, domes, micro USB port, antennas, vibrator motor, microphone, speaker, rear camera module, flash module, adhesive materials, EMI shielding components, cables, screws and fasteners.

Machines used: Automated Screwdriving Machine, Automated Gluing Machine, RF Testing Equipment, Automatic Wrapping Machine, Automated Dispensing Machine, Bar code reader, IMEI label generator machine

Manufacturing process :

Experience the flawless assembly process of Walton feature mobile phones, where every detail is meticulously attended to. The journey begins with expertly soldering the peripherals to the PCBA, ensuring seamless integration. The functional DOM is then delicately applied to the PCBA keypad side, bringing the device to take user’s command. The magic continues as the PCBAs with peripherals find their perfect place in the Middle Housing, showcasing precision engineering at its finest. Moving forward, the Front Housing gracefully comes together with the Middle Housing, effortlessly accommodating essential components like Camera Lens and LCD Lens. These elements not only enhance the device’s structural integrity but also add a touch of elegance to its overall visual appeal. And finally, the Back Housing is skillfully attached, completing the masterpiece that is your Walton feature mobile phone. Experience innovation, quality, and style fused into one seamless process, delivering a mobile phone that exceeds expectations and satisfies even the most discerning users.

Throughout the entire production process, stringent quality control measures are strictly enforced. From the initial inspection of incoming materials (IQC) to meticulous checks at each stage through Line QC, no aspect is overlooked. The production line operates within a controlled environment, employing clean rooms to maintain a pristine atmosphere and prevent contaminants from affecting the device’s quality. To safeguard sensitive components, thorough measures are in place to prevent Electrostatic Discharge (ESD). Automation technologies play a crucial role in enhancing efficiency, with auto screwing and auto gluing machines ensuring precise and consistent attachment, while RF and automatic wrapping machines enable seamless packaging. Real-time monitoring of the process allows for immediate adjustments and quality assurance. The culmination of these efforts, combined with the expertise of a skilled workforce, guarantees that each mobile device meets the highest standards of quality and performance