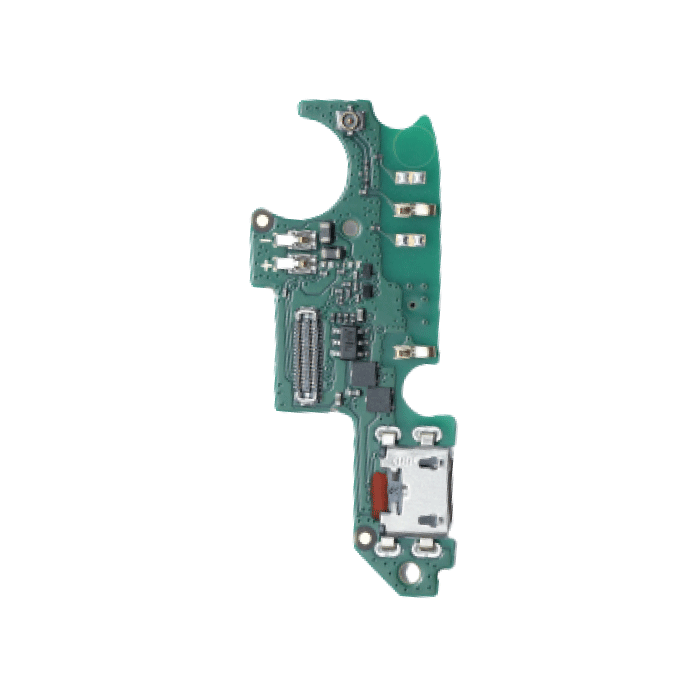

Description

Raw Material: Printed Circuit Board (PCB), Integrated circuits ( Chipset, Ram, Rom, PMU, PA, RF IC etc), resistors, capacitors, inductors, diodes, transistors, connectors, sensors, EMI shields Stencil, Solder paste, Glue, Underfill material.

Machines: Auto Loader, Solder paste printer, Pick and place, Reflow oven, AOI, routing, SW, RF, ATA jig

Process:

The process of smartphone PCBA SMT (Printed Circuit Board Assembly Surface Mount Technology) involves several crucial steps and equipment. The production line begins with an Auto Loader, which efficiently loads the PCBs onto the assembly line, reducing manual handling. The Solder Paste Printer then applies solder paste to the PCB pads using a stencil, ensuring precise placement. The Pick and Place Machine accurately positions the various components, including Integrated Circuits (such as chipsets, RAM, ROM, PMU, PA, RF IC), resistors, capacitors, inductors, diodes, transistors, connectors, and sensors, onto the solder paste. The PCB then proceeds to the Reflow Oven, where the solder paste is melted, forming secure electrical connections. Automated Optical Inspection (AOI) systems carefully examine the PCB for defects using cameras and image processing algorithms. Routing equipment is used to shape and remove excess PCB material. Software (SW) is responsible for programming and configuring the smartphone’s functionality. RF components enable wireless communication, while an Automated Test Equipment (ATA) Jig performs automated functional testing.

Walton SMT, in line with RoHS regulations, boasts a state-of-the-art production line that incorporates the latest technology and innovative features. The IQC (Incoming Quality Control) procedures rigorously assess incoming materials to maintain superior standards. Additionally, the production line includes ATA (Automated Test Equipment) for comprehensive testing and validation of the finished products. To preserve solder paste quality, it is stored under optimal conditions within a standard environment. A sophisticated component storage system ensures inventory accuracy and proper handling. Furthermore, FMEA (Failure Mode and Effects Analysis) analysis is conducted to identify and mitigate potential risks, ensuring robust manufacturing processes. With these cutting-edge features, Walton SMT’s production line stands as a pinnacle of efficiency, accuracy, and compliance with industry standards.