Description

Raw materials: Roll of cable, PCBA

Machines used: Wire cutting and stripping machine, insulation removing machine, cutting pliers, foil twisting machine, automatic soldering machine, molding machine, harness tester,

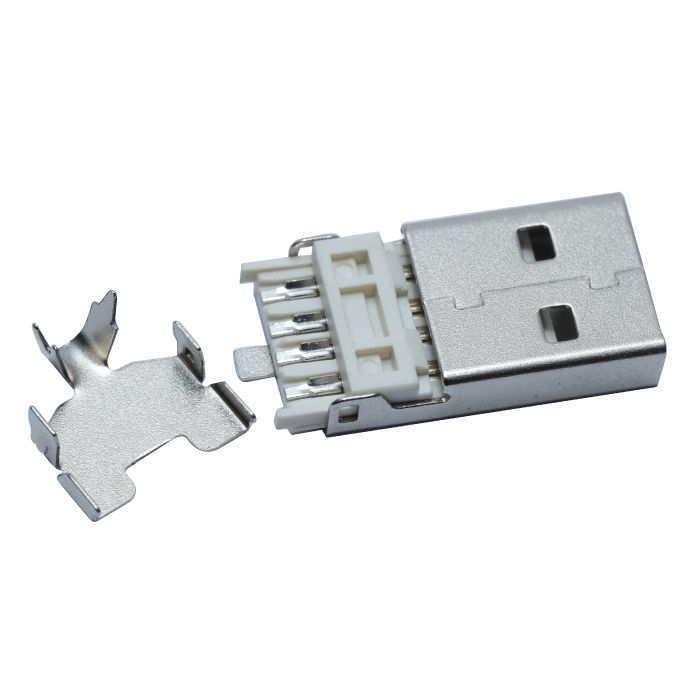

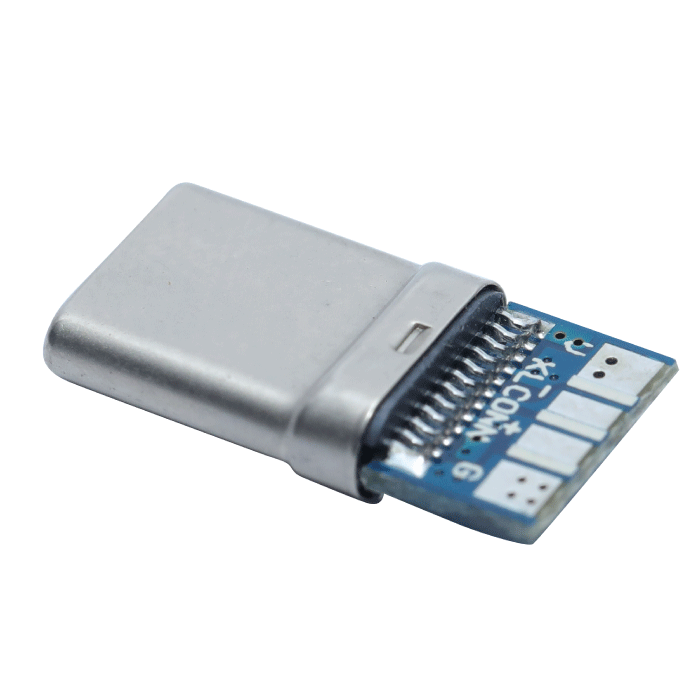

Manufacturing process: Firstly cables are cut by using wire cutting and stripping machine. Wire cutting and stripping machines are designed to cut cables and precisely strip off the insulation from the ends of wires. They ensure consistent and accurate cuts, resulting in uniform wire lengths and stripped ends. This level of precision is crucial for maintaining the quality and functionality of the cables. Cutting length of cable is 1 meter. Using insulation removing machine and cutting pliers, insulator wires are removed. After that foil twisting machine is used for shielded wire twisting. Applying automatic soldering machine, 4 types of wire (red, white, green, black) is soldered with PCBA in C side and 4 types of wire (black, green, white, red) is soldered with A side connector. Sequence of 4 wires both in A and C side is maintained correctly. Automatic soldering machines ensure consistent and reliable solder joints throughout the cable manufacturing process. These machines are designed to precisely control the soldering temperature, time, and flow, resulting in uniform and high-quality solder connections. This consistency is essential for maintaining the electrical conductivity and mechanical strength of the soldered joints. Molding machine is used for completing PE molding, PVC molding both in A and C side applying ABS. Packaging is started after checking all functional parameters using harness tester.