Description

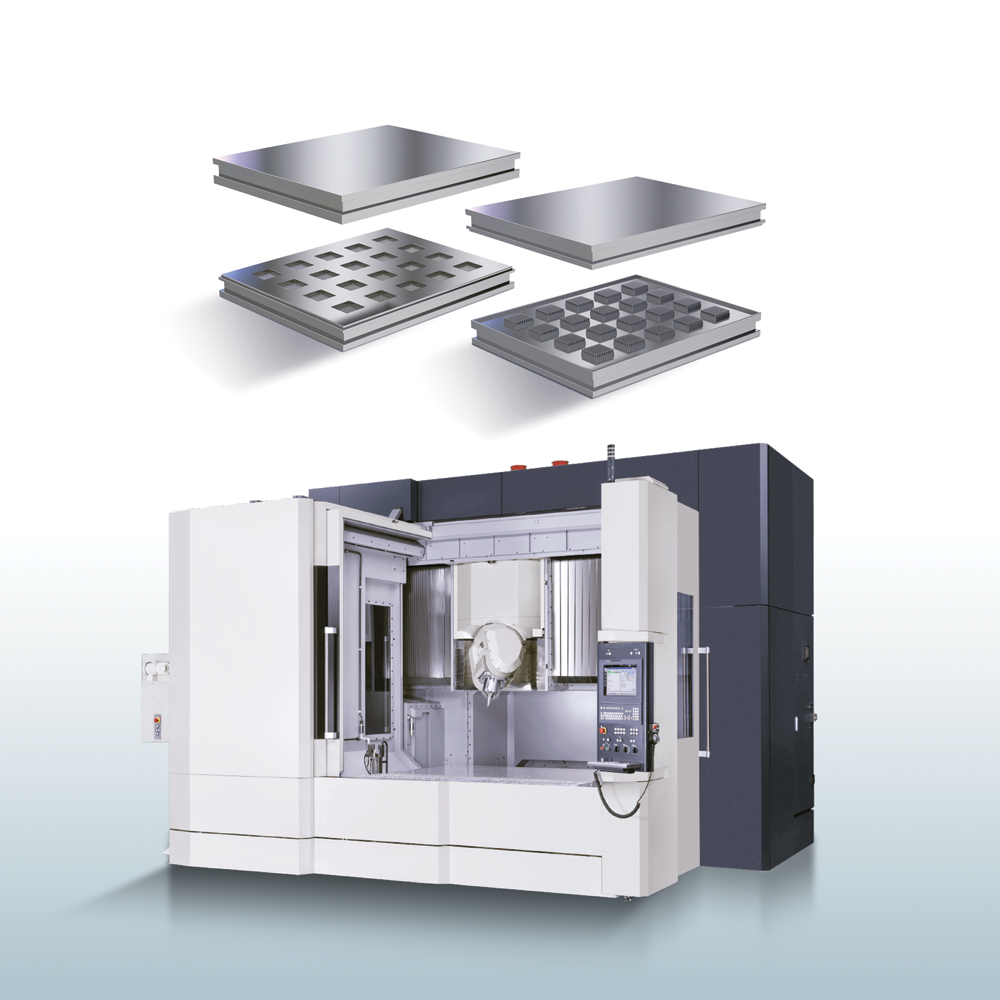

- Thermoforming mold: Vacuum & pressure forming, High Glossy. COMI/ASANO/KIEFEL/King power machine compatible. Mold Dimension up to: L-2250mm, W-1500mm, H-850mm.

- PU foaming mold: Temperature controlled & highly product accuracy. Dimension up to: L-2000mm, W-800mm, H-700mm.

- PU foaming jig: Automatic, Semi-automatic & manual foaming jig. Durable & high quality foaming jig.

- Jig Dimension up to: L-2500mm, W-1700mm, H-1150mm.

- Styrofoam Mold: Low & high density product can be manufactured. Highly product accuracy.

- Dimension up to: L 2000, W-1700, H-450 mm.

- Prototype: Automatic & manual prototype manufacturing for mockup test, dimension test & assembly check of final product.

- Materials used: Aluminum, Brass, Copper, MS, SS, SKD11.

- Highly skilled & Experienced design & manufacturing team.

Application:

- Thermoforming mold is used in thermoforming process to produce inner liner of refrigerator compartment (Mainly Door Liner & Cabinet Liner). Thermoformed products are being widely used in a variety of industries including the packaging, transportation, appliance industry, horticulture, recreation, photographic equipment and funeral industries.

- PU foaming mold & jig are used during refrigerator cabinet & door foaming. In this process polyurethane material is injected between the steel case and the inner plastic liner.

- Styrofoam mold is used to produce inner assembly part for air flow guide & packaging part of refrigerator. It is also used to produce packaging part of electrical appliance, home appliance, industrial packaging & different insulation product.

- Prototype components are used to assure dimensional, aesthetical & assemble accuracy of final parts/components of a product.

Reviews

There are no reviews yet.