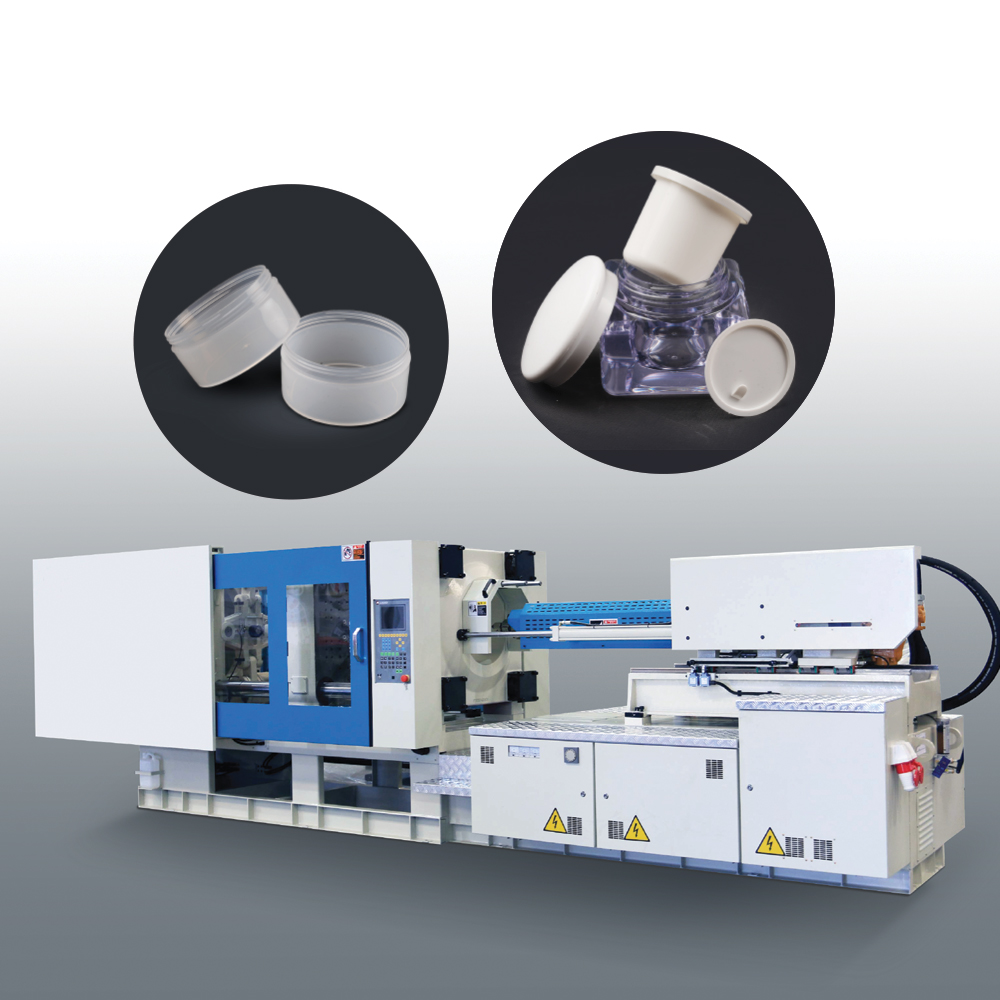

Description

- Horizontal Machine : (60 – 2100) ton

- Vertical Machine : (15 – 75) ton

- Machine Size : Small, Medium, High

- Product Weight Range : 10 gm to 10 kg

- System : Rapid Heat Cycle Molding (RHCM) & High Speed Machine

Facilities of Injection Mold:

- Material Process: ABS, HIPS, POM, PP, Milestomer Rubber, Soft PVC.

- Available Machine Screw Type: A, B, C & D Type.

Application:

Manufacturing mass amount of plastic parts within machine tonnage.

- Electrical & Electronics Goods Plastic Parts

- Mobile & IT Products Plastic Parts

- Household Plastic Items

- Packaging & Other Plastic Items

- Medical Plastic Items

- Kid’s Toys