Description

| Type of Material | Material Thickness, mm | Mother Coil Information | Child Coil Information | Side Trimming Allowance | |||||

| ID, mm | OD, mm | Width, mm | Weight, Ton | Width, mm | Coil Qty | Weight, Ton | |||

| PPGI Sheet | 0.2~1.2 | 508/610 | 1000~1450 | 900~1400 | 3.5~10 | 25~690 | 2~30 | 1~4.5 | 3~5 mm (Both Side) |

| GI Sheet | |||||||||

| Aluzinc Steel Sheet | |||||||||

| EGI Sheet | |||||||||

| Cold Rolled Mild Steel Sheet | |||||||||

| Cold Rolled Non-Oriented Silicon Steel Sheet | 0.35~0.5 | ||||||||

Application:

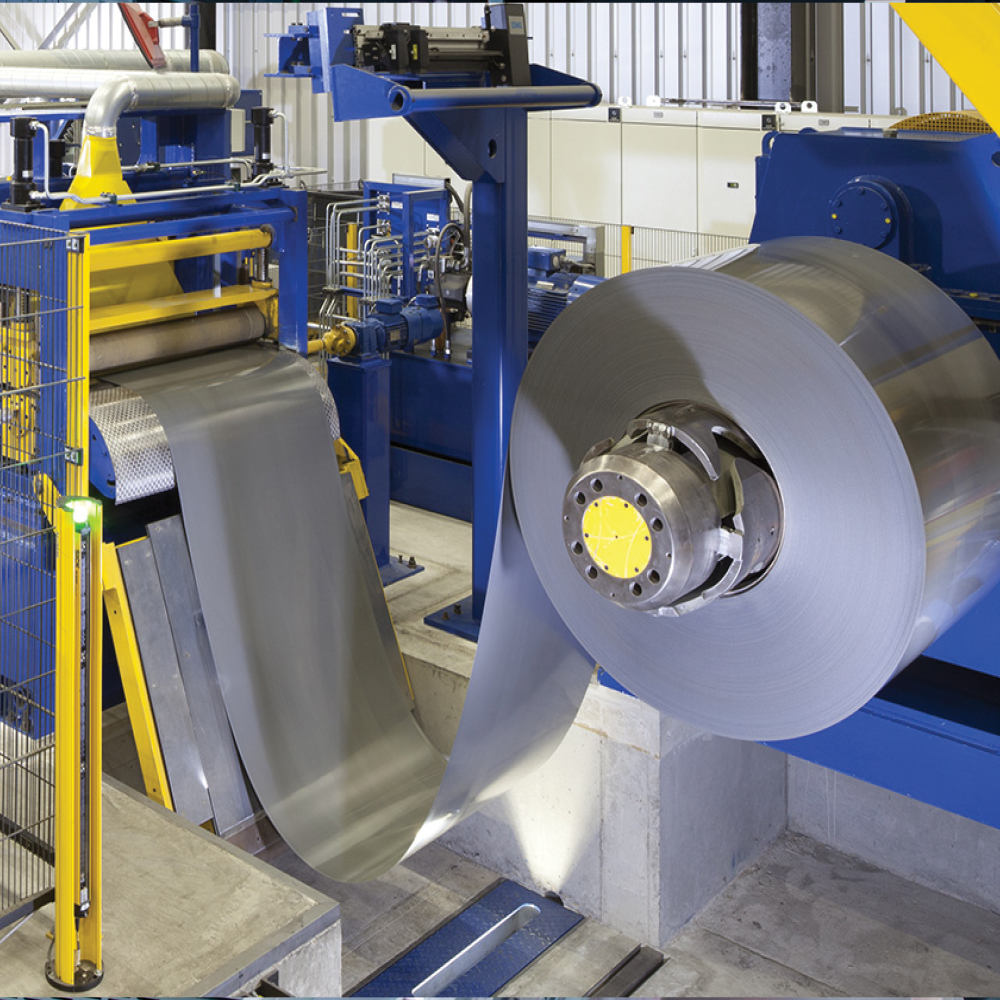

A sheet metal coil slitting machine is a specialized piece of equipment used to cut wide metal coils into narrower strips or rolls. This process is essential for various industries that require customized widths of sheet metal for specific applications. Here are the key applications of a sheet metal coil slitting machine: Automotive Industry, HVAC Systems, Electrical and Electronics, Building and Construction, Packaging Industry, Furniture and Appliances, Metal Fabrication, Energy Sector and so on.

Reviews

There are no reviews yet.